- Sustainable Planet -

- 6mins -

- 780 views

Tech upgrades complete, The Ocean Cleanup is set to relaunch in June to rid our oceans of plastic

With new and improved system design upgrades now complete, The Ocean Cleanup, Dutch entrepreneur Boyan Slat’s ambitious project to clean the sea, will relaunch next month.

The Ocean Cleanup: all systems go for a June relaunch

Last September, The Ocean Cleanup, 24-year-old Dutch entrepreneur Boyan Slat and his team’s ambitious project to rid our oceans of plastic, deployed System 001 into the Great Pacific Garbage Patch – marking the first-ever attempt to start cleaning it up.

During that campaign the team were able to confirm many key assumptions of the design, however they also encountered two unscheduled learning opportunities: the system did not maintain a sufficient speed, allowing plastic to exit the system; and a stress concentration caused a fatigue fracture in the HDPE (High Density Polyethylene) floater. With these issues now resolved, the improved system will be redeployed in June.

The Ocean Cleanup System 001/B has various modifications to improve performance

Last September, The Ocean Cleanup launched their first system with the aim of achieving proof of technology and commencing cleanup. Twenty years after the discovery of the Great Pacific Garbage Patch, this was the first time a system was deployed to start to clean it up. They did this after completing hundreds of scale model tests and a series of nearshore prototypes.

Yet, when launching the system, they knew and had to accept that a degree of uncertainty remained. This makes sense, as something like this has never been attempted before. Especially when considering the interaction between the system and the plastic, there was no way to test it before deploying a cleanup system in the Great Pacific Garbage Patch. Hence, they must learn by doing, developing the technology in an iterative fashion as they go.

During the first four months that the system was offshore, the team were able to confirm many of the key features of the cleanup system. But they also encountered some unscheduled learning opportunities; notably:

- the system wasn’t able to retain the plastic it caught

- the floater suffered from a structural failure, causing an 18-meter end section to disconnect from the rest of the system, just before the end of 2018.

With these fresh insights from the root cause analysis, Slat and the engineering team began to work on solutions that they could start trialing in the Great Pacific Garbage Patch (GPGP) this year.

The upgraded design, which they have dubbed System 001/B, will entail various modifications (see below) that will be tested during their next campaign beginning in June.

By adapting the design to address these unforeseen learning opportunities, the team are aiming to perfect a system that can effectively capture plastic while withstanding the natural forces of the ocean.

Source: TheOceanCleanup

Structural design improvements and smaller electronics systems will be trialled in June

Survivability is essential if Slat and The Ocean Cleanup team intend to keep their systems deployed for long periods of time and expect them to endure the harsh winter months in the ocean.

In addition to the modifications detailed below, the main improvement of the structural design was to simplify the HDPE pipe and allow minimal fluctuations in the wall thickness.

The following they aim to test in the next campaign beginning in June:

- New screen design – because the rail connection (dovetail connection) was the cause of the fatigue fracture, they have completely eliminated this aspect of the design by bringing the screen slightly forward and connecting it to the pipe using slings. This simplifies the connection to the system and should allow us to minimise stress concentrations.

- Eliminate stabiliser frames – to ease the loads on the pipe, we will not use the stabiliser frames. By simplifying the electronics on this design in particular, we no longer require these frames, as they were primarily there to prevent the system from toppling over from the weight of the electronics.

PLASTIC RETENTION

To effectively remove vast amounts of plastic, the system needs to be able to catch and retain plastic for long periods of time with minimal plastic loss. To retain the captured plastic, it is not as important if the system moves slower or faster than the plastic, rather the key is consistency: the velocity different must either always be positive or negative. In other words, the system must always go faster than the plastic or always go slower than the plastic. Fluctuations in the speed will prevent the plastic from staying within the system – as we saw during the previous campaign.

Because this topic is essential for cleanup, they will test two options that will either speed up the system or slow it down. They are:

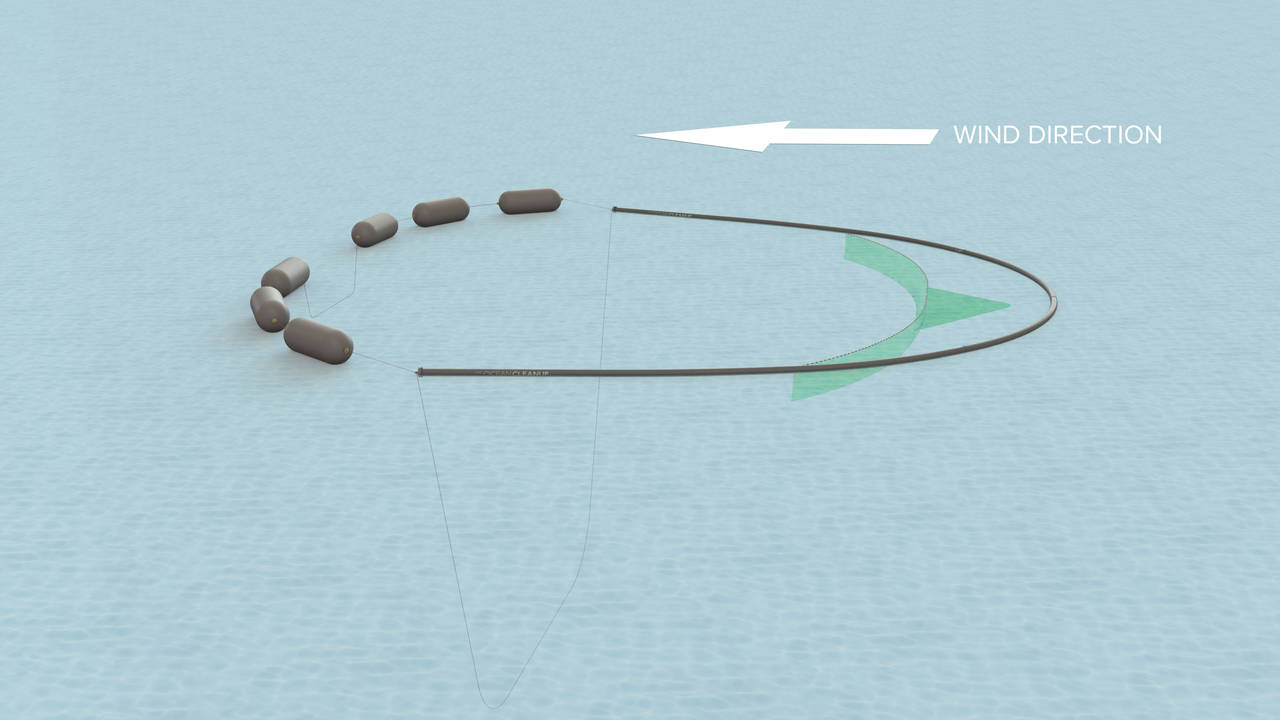

- Inflatable buoys – one idea was to add a sail to increase the windage of the system, but the loads from a sail would be too great during storms – approximately five tons of force for every meter of sail. The force would cause the system to topple over, resulting in complicated structures to keep it upright. This option was, therefore, not feasible. However, this thinking did lead to the idea of disconnecting the sail from the floater and let the sails float freely. To test this idea, they will trial giant inflatable buoys on the front of the system which will tow the system forward, propelled by the force of the wind.

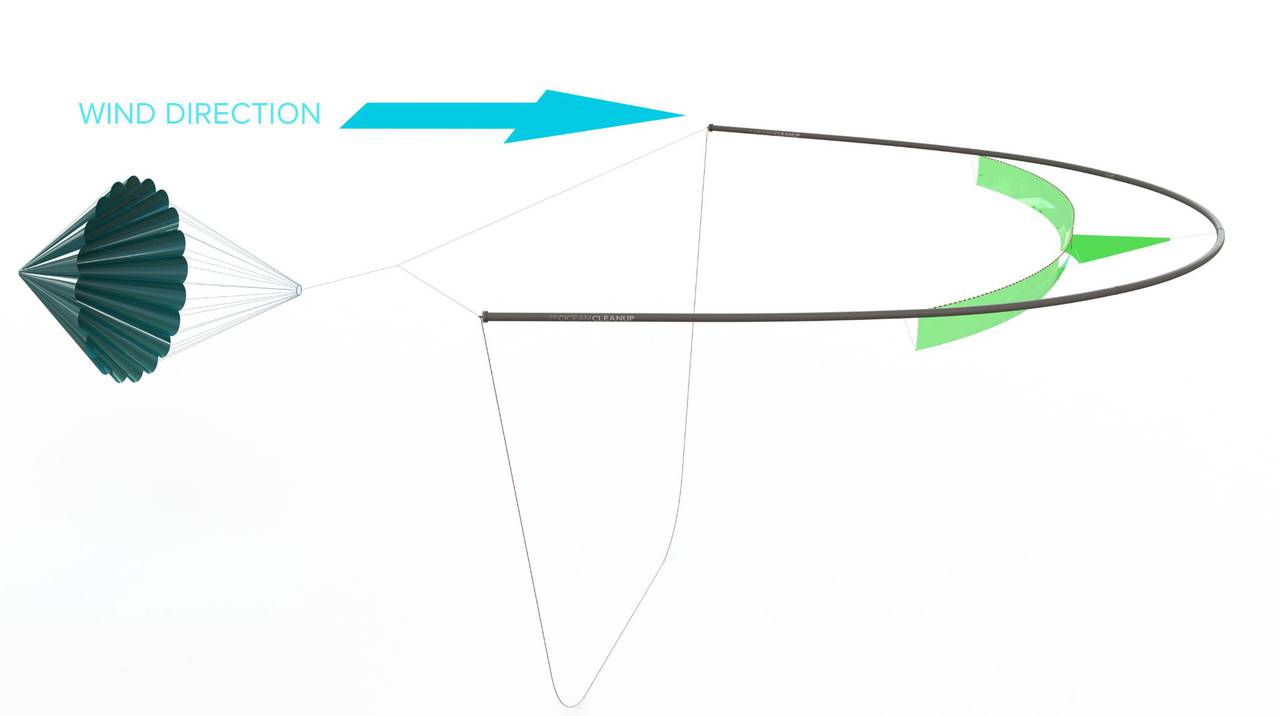

- Sea anchor – an alternative option, should the buoys prove ineffective at speeding up the system, is to attach a massive 20-meter-diameter parachute-like sea anchor, which will turn the system around and, in theory, maintain a slower speed than the plastic. Rather than attempting to go faster than the plastic, this option brings the speed close to the speed of the water, making use of the observation that the plastic can travel substantially faster than the water current.

Side note:

If you are familiar with previous designs, the parachute option (pictured below) might sound similar to the deep-sea drift anchor they proposed in May 2017. The benefit of the parachute is that it will operate at the free surface in the same water layer as the system, whereas the anchors would be subjected to deeper ocean currents; and, since the current profile changes speed and direction over depth, it is better for the behavior of the system to have this functionality subjected to the same forces as the system.

TEST, LEARN, REPEAT

The basic principle behind the iterative design process is to test, learn, and repeat until you have a proven concept. The Ocean Cleanup team do not know with certainty that these proposed options will solve the issues they have encountered.

In fact, there may still be further unknowns, as is the nature when doing something that has never been done before.

What they do know with certainty is that every day they are not yet operational the plastic pollution problem is not getting better.

This is why it is important to return to the Great Pacific Garbage Patch as soon as possible, test these options, and make the necessary adjustments from these findings, also, as quickly as they can.

During the last campaign, the team learned that some of their processes hindered quick iteration cycles. This led to two additional changes to their approach:

1. Smaller system design – This time they are reducing the size of the system by a factor of three, which means they can speed up the procurement and assembly processes, as well as the tow, and be return to the patch next month, rather than next year.

2. Modular approach – the designs they will be testing are much more modular. This ensures they will be able to make significant changes while offshore, preventing them from having to return to land (a time prohibitive process). This approach lets them speed the system up, slow it down, adjust the rigging, implement different screen types – thus, increasing the cycle speed of iterations and reaching proof of technology much faster than they otherwise would.

LOOKING AHEAD

System 001/B is aimed at proving the technology; however, The Ocean Cleanup team accept that they might find more unknowns that will lead to further adaptations to the design. In either case, they say they expect to learn more about the overall system design and the performance of our technology with this system. This system will return to shore once they can/cannot confirm the proposed solutions and they will move forward with the necessary redesigns with these learnings.

Slat and the team say they expect these next few months to be exciting and informative for The Ocean Cleanup project.

You can stay updated through their social media channels as they learn more. Instagram – Facebook – Twitter – YouTube – LinkedIn

Source: TheOceanCleanup.com