- Sustainable Planet -

- 4mins -

- 1,684 views

Indian startup recycles the un-recyclable into construction alternatives to plywood and cement

Rincron is a sustainable startup whose business model is to recycle problematic multi-layer plastic waste into sturdy sheets that can be used to build other things, working towards a circular economy for India and beyond.

Novel solution to tackle hard to recycle plastic waste

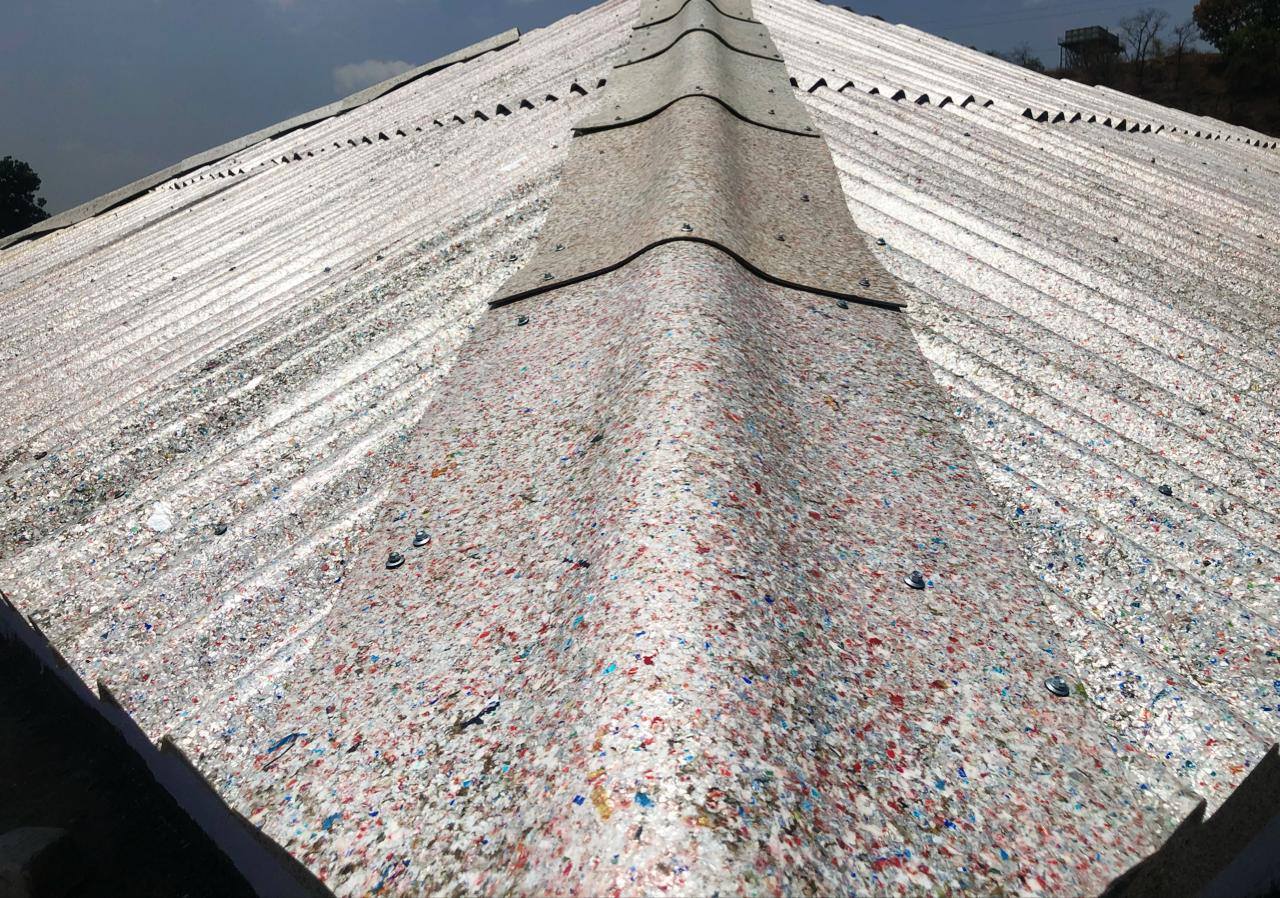

Gujarat-based Rincron Panels recovers usually non-recyclable multi-layer plastic trash and uses its propitiatory technology to convert this waste into sheets of different thicknesses that are then used as a building material. As a potential substitute for plywood, cement and corrugated metal sheeting, Rincron Panels have a lot going for them; they’re corrosion-proof, heat resistant, fire retardant, termite-proof, and waterproof.

A circular economy

With the world’s population expected to peak at 10bn in 2050, the earth’s resources are not limitless. As a result, global labour and raw material costs are on the rise.

Currently, 40% of plastic waste in India ends up being uncollected for recycling. Proper management of this waste can create 1.4 million jobs and could potentially represent a $2bn opportunity. A Circular Economy seeks to eliminate any kind of underutilisation of resources or assets.

In a circular economy, products and materials keep circulating in a high value state of use, through supply chains, for as long as possible.

Products are designed and built so that they are part of a value network where re-use and refurbishment on a product, component and material level assures continuous (re-)exploitation of resources.

Source: Ricron

The Hazards of MLP waste

Multi-layered plastics (MLPs) are made up of a layered composition of various types of plastics. This is a commonly used method because of the properties that the thus composed material acquires.

Sometimes, the plastics material is also combined with non-plastics such as aluminium foil. Neither multi-layered plastics products made up of only plastics nor those made up in combination with a non-plastics material can be recycled.

Ricron are able to contribute to the problem of handling waste that has no means of recycling and converting it into useful products that can be used as a substitute to wood-based products.

Their propitiatory technology allows them to convert this MLP waste into different forms of sheets that are used as a building material, from flooring to roofing, and formwork shuttering to partition walls. They say conversion of this waste is with minimum usage of energy and without any harmful impact to the environment. Ricron do not produce any waste.

Formed in 2014, the Gujarat-based company currently recycles 500 tons of MLPs each day

Last week, Rahul Chaudhary, the director of the company, told The Better India that he chose this venture to address a pressing environmental issue.

“The Union government also mulled over phasing out ‘non-recyclable multi-layered plastic’. But a blanket ban of MLPs would be too disruptive for the industry as well as the economy,” he said.

The big issue, Rahul says, is that used MLP products receive low value, such as Rs 1.5-2 per kilo (2-3 cents), and are complex to treat. Moreover, the plastic either ends up in landfills or has to undergo incineration. If not processed in the appropriate manner, it releases toxins and gases that harm the environment.

“Hence, we decided to address the issue by converting them into recycled boards. It also helps to reduce the burden on the forests as it serves as a viable alternative for plywood,” Rahul says.

In 2019, Ricron received the Green Pro Certification Award from the Confederation of Indian Industry (CII) and the Climate Solver Award by World Wildlife Fund (WWF) India for its innovative solutions to tackle the plastic waste challenge.

Rahul says the company plans to set up more manufacturing centres across India and sell the product overseas. “We plan to increase plastic waste mitigation from 500 tons a day to 1,000 tons in future,” he added.

Source: TheBetterIndia