- Inspiring People -

- 5mins -

- 298 views

College Students Win Design Award for Device That Curbs Microplastics Emitted From Tyres

Four students at Imperial College London have won this year’s James Dyson Award for their device to capture micro-plastic emissions from vehicle tyres.

Tackling toxic tyre emissions: student inventors win Dyson Award

Four Imperial College London students have won this year’s James Dyson Award for their device to curb microplastic emissions from vehicle tyres. The Tyre Collective, founded by students from the Dyson School of Design Engineering, won the UK prize of the international design competition with their solution to the growing problem of pollution caused by tyre wear from vehicles. Their device captures microplastic particles from tyres as they are emitted and could help to reduce the damaging pollution they cause.

The Tyre Collective: Saving our air from tyre wear

The Tyre Collective, founded by students from the Dyson School of Design Engineering, won the UK prize of the international design competition with their solution to the growing problem of pollution caused by tyre wear from vehicles.

Their device captures microplastic particles from tyres as they are emitted and could help to reduce the damaging pollution they cause.

Wear and Tyre

Every time a vehicle brakes, accelerates or turns a corner, the tyres wear down and tiny particles become airborne, producing half a million tonnes of tyre particles annually in Europe alone.

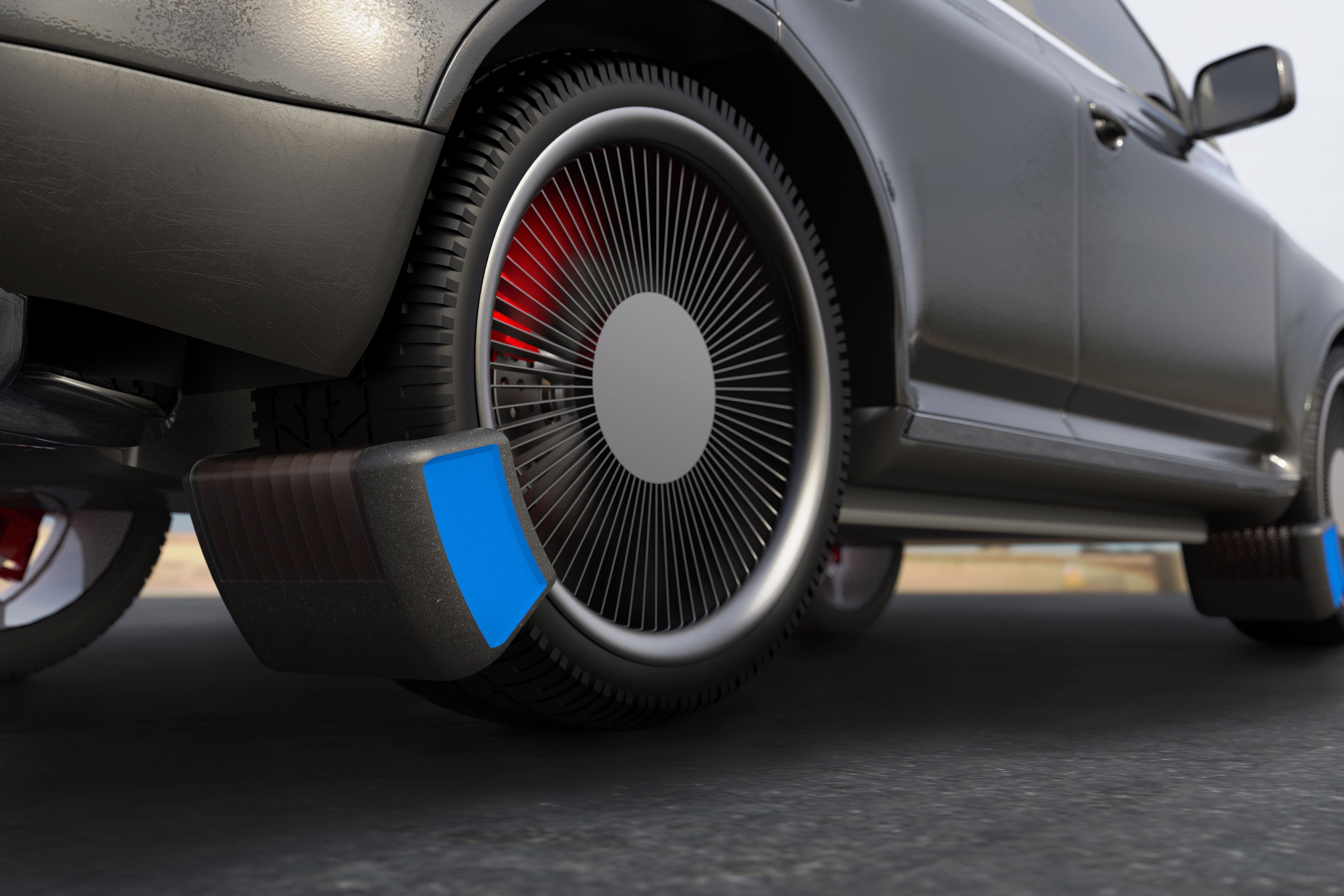

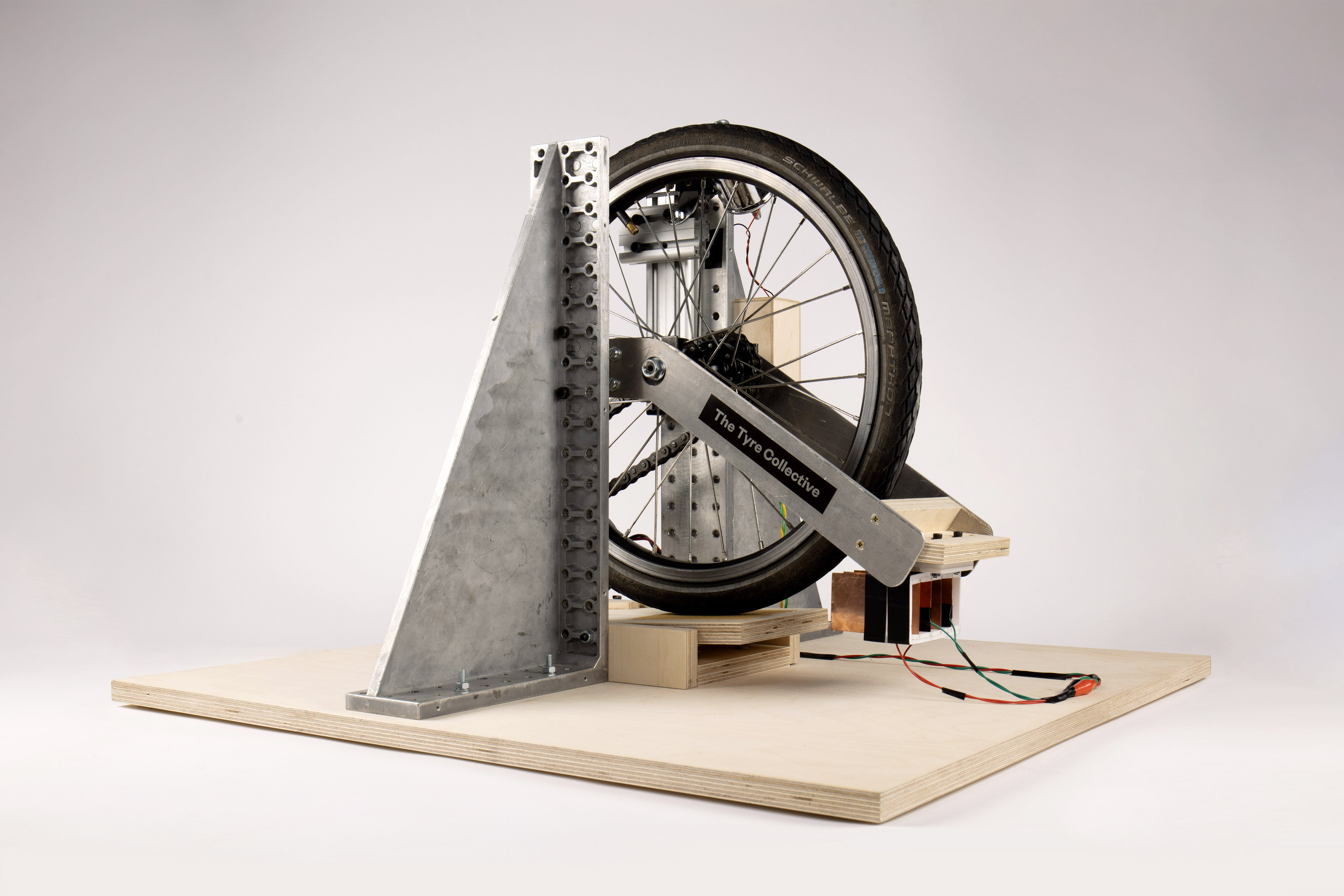

The team’s winning device is fitted to the wheel of the vehicle and uses electrostatics to collect particles as they are emitted from the tyres, using air flows around a spinning wheel. They claim that their prototype can collect 60% of all airborne particles from tyres, under a controlled environment on their test rig.

Once collected, the fragments can be reused in new tyres or other materials such as ink. The Tyre Collective have demonstrated this by printing their business cards using ink made from collected tyre dust.

Source: Imperial.ac.uk

It’s common knowledge that tyres wear down, but nobody seems to think about where it goes

The team are made up of students Siobhan Anderson, Hanson Cheng, M Deepak Mallya, and Hugo Richardson who all studied Innovation Design Engineering, a course offered jointly by Imperial College London and the Royal College of Art.

“As a team, our strength lies in our diversity,” Hugo Richardson told The Guardian. “We come from all four corners of the globe and bring with us a wealth of knowledge in mechanical engineering, product design, architecture and biomechanics.

“It’s common knowledge that tyres wear down, but nobody seems to think about where it goes, and we were really shocked to discover that tyre particles are the second-largest microplastic pollutant in our oceans. At the Tyre Collective, we incorporate sustainable and circular values into product design to capture tyre wear at the source.”

The World Health Organisation estimates that outdoor air pollution causes 4.2 million premature deaths worldwide per year. Most air pollution related deaths are linked to exposure to small particulate matter of 2.5 microns or less in diameter, which can penetrate deep into the respiratory system. Their harmful effects on health include cardiovascular and respiratory disease, as well as cancers.

Greater adoption of electric vehicles will cause a reduction in exhaust emissions, but tyre dust will continue to pollute the air. The team estimate that tyre emissions may even increase, as electric vehicles are heavier due to the added battery weight.

Source: Imperial.ac.uk

The device is intended as part of a closed-loop system

The team discovered that rubber particles coming off the tyre are positively charged due to friction. Using a single array of electrostatic plates, our design currently captures 60% of all airborne particulates on a test rig. It is low energy and can be powered directly from the car’s alternator.

The tested solution is the result of collaboration with experts in Aerodynamics and Material Science from Imperial College, facilitated by design.

Positioned close to where the tyre meets the road, with sufficient ground clearance, the device takes advantage of various air flows around the spinning wheel. It is attached to the steering knuckle, free to move and turn with the suspension, and adaptable to different vehicles. Captured tyre particles are stored in a cartridge within the device and collected during servicing. Once refined, they are extracted and used in a variety of applications, including new tyres, 3D printing and dyes, creating a closed-loop system.

The James Dyson Award, which is in its 16th year, operates in 27 countries and is open to university students and recent graduates studying product design, industrial design and engineering. It recognises and rewards imaginative design solutions to global problems with the environment in mind.

Source: JamesDysonAward.org