- Better Society -

- 3mins -

- 76 views

$1 Glasses help 150 Million Worldwide to see

Specs appeal: German physics teacher and OneDollarGlasses founder Martin Aufmuth wants to help the whole world to see affordably with these innovative and inexpensive reading glasses.

Worldwide approximately 150 million people need a pair of glasses but cannot afford them

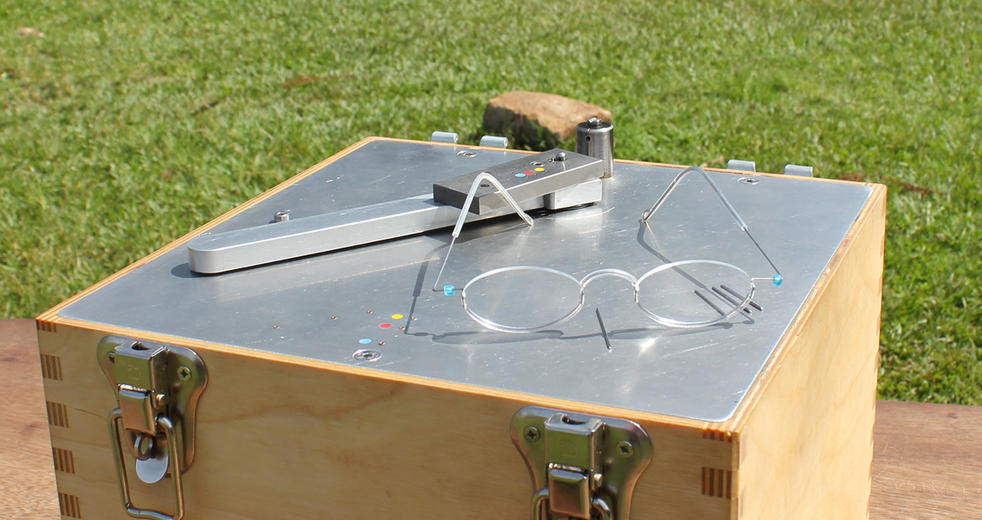

They cannot learn or work and are unable to provide for their families. The solution: The OneDollarGlasses. They consist of a lightweight, flexible spring steel frame and prefabricated lenses and can be locally manufactured with simple bending machines. The materials, per pair, cost approximately $1US.

Newly-trained opticians are able to start their own businesses

The World Health Organisation (WHO) estimates as many as 150 million people around the world suffer from poor vision. Unaffordable eye tests, glasses and contact lenses often lead to permanent vision damage that could be avoided. High costs for eye care can result in decreased economic opportunity, as uncorrected poor vision limits or eliminates opportunities to attend school or gain employment.

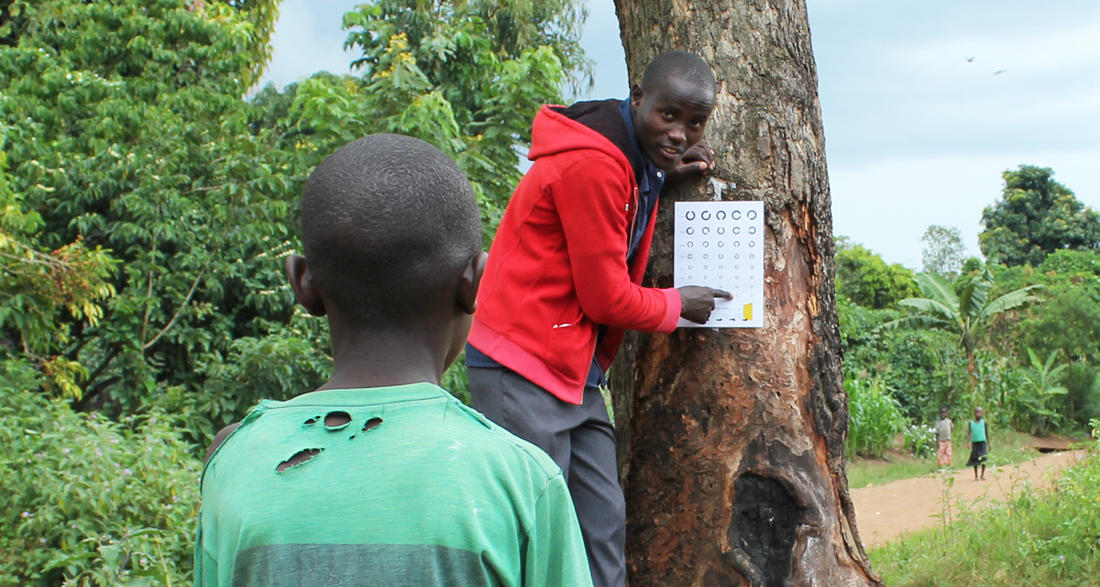

Since 2012, the OneDollarGlasses Association, founded by Martin Aufmuth in Germany, has been training new opticians in Uganda, Rwanda, Burkina Faso, Tanzania and Bolivia to manufacture glasses that have a total material cost of $1US and are sold for $2-7 each.

Not only are customised glasses created at an affordable price, but the newly-trained opticians are able to start their own businesses, provide for their families, and make a difference in the lives of their neighbours. The goal of the organisation is simple: to provide people around the world that are living on $1 per day with affordable glasses.

Source: innovatedevelopment.org

The machines do not require electrical power and are provided for free

The glasses are made of lightweight spring steel frames and prefabricated polycarbonate (a relatively break-resistant material) lenses, and take about 10-30 minutes to produce. Aufmuth began experimenting with methods of manufacturing inexpensive glasses in 2009, and by 2012 had created the OneDollarGlasses bending machine that shapes the spring steel into one of three frame sizes, allowing the opticians to produce glasses for children and adults alike. These machines do not require electrical power and are provided to OneDollarGlasses-trained opticians for free in a box with all materials necessary for the production. Up to four opticians can work simultaneously on one machine, resulting in a yearly production capacity of 20,000 to 50,000 pairs.

Source: innovatedevelopment.org

OneDollarGlasses are custom-made for each patient

OneDollarGlasses provides a simple and innovative solution that contributes to global development in a number of ways. In contrast to donations of used glasses, the most common solution for the correction of poor vision throughout the world, OneDollarGlasses are custom-made for each patient, guaranteeing a comfortable fit and an accurate prescription, as well as a choice of two coloured beads to decorate the frames. Additionally, local production provides economic opportunity to the newly-trained opticians and only requires a short training period of two weeks. The process is especially useful in rural regions because the boxes containing the bending machines and materials are small and portable, meaning opticians are able to travel to different cities and villages as opposed to patients seeking out care.

(excerpt from a report by Eric Anderson for Innovate Development in May of 2014. Click for full report)

Source: innovatedevelopment.org