One company is solving plastic waste in Indonesia with edible, eco-friendly and biodegradable bioplastics made from sustainably produced seaweed, which can be used as an alternative to traditional plastic packaging.

Evoware: edible alternatives to plastic packaging

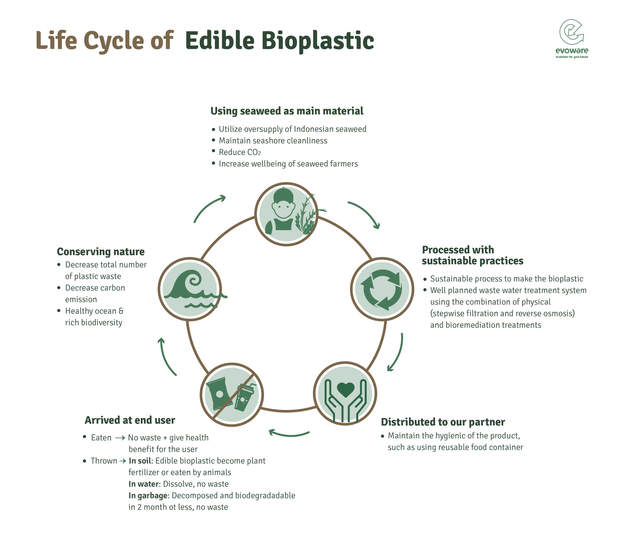

Evoware is a socially responsible enterprise that promotes an environmentally friendly lifestyle and provides innovative value to Indonesia’s urban society. Through Evoware’s products, it is hoped people will evolve to be closer to nature and live a more responsible and sustainable life. The company say they are here to be the eco-solution for plastic waste problems. All their products are eco-friendly, biodegradable, with some even edible and healthy for the body. How? They use seaweed as their raw material. Their impact is not just for the environment but also for the livelihood of the seaweed farmers.

Evoware produces edible and biodegradable sachets and wraps directly made from seaweed

Indonesia is the world’s second biggest contributor of plastic waste into the ocean. As much as 90% of Indonesia’s plastic waste ends up in the ocean. Plastic waste turns into nano- and micro-plastic particulates, which are then mistaken by sea animals for food. More than 1 million sea animals die every year because of plastic waste, and more than 25% of the fish sold in the markets is contaminated by plastics.

The flip-side of this is that Indonesia is blessed with a lot of natural resources, including abundant seaweed that unfortunately can’t be absorbed fully by the market. To solve both problems, Evoware provides a solution to create innovations that can contribute to end plastic waste issue, with seaweed as the main material.

Bioplastic is now an emerging material available in the marketplace. The big three biomaterials are poly lactic acid, poly hydroxyl butyrate, and starch. What Evoware propose is an edible bioplastic, made from nutritious material without involving any chemical. It is good not only for us humans, but also for plants as fertiliser.

Evoware designed two types of edible bioplastic as substitutes for small-format plastic packaging and metalized-laminated sachets: Single layer seaweed-based edible sachet for dry food products; Dammar-coated seaweed-based edible sachet for liquid and semisolid food products.

Source: Challenges.Openideo

So what’s the big deal with seaweed?

- This seaweed is nutritious, safe, has no allergy risk, and is halal, which is important in Indonesia

- It’s abundantly available throughout the year

- The agriculture is easy and only needs 45 days to cultivate

- Its waste can be used as fertilisers for plantations

- It can only grow in healthy environments, so seaweed farmers will actively participate in maintaining the cleanliness of the seashore

- Compared to the bioplastic from land crops, such as cassava or corn, the sustainability, quality and scalability of seaweed-based edible bioplastic is better

- Indonesia has thousands of islands that have not been utilised to cultivate seaweed, so the raw material availability is secured

- The products are made directly from seaweed without/converting it into carrageenan, so it does not use chemicals nor possess any harmful effects.

Source: Challenges.openideo

What are the potential applications?

The potential applications are to solve the existing small-format plastic packaging that’s too light or worthless to be recycled:

- Sachets for dry food products such as but not limited to coffee, creamer, sugar, cereal, salt, pepper, and seasonings in instant noodles. Those products come with either single or metallized-laminates plastic packaging in the small formats. Based on the survey from Asia Food Journal, these conventional packaging aren’t convenient and may cause stressful feelings when the end consumers are in hurry.

- For liquid and semisolid food products, such as, but not limited to, sauces and seasoning oil in instant noodles.

- Food wraps comprising burger/sandwich and rice wraps. It is produced as a thin sheet to substitute plastic-laminated paper in which the plastic too light (its plastic is only about 20% (or 0.32 gram) from the whole paper)

- There are other potential applications of seaweed-based edible bioplastic. Not only for food products, but also for other small-format packaging, such as soap, shampoo, toothpick, straw, sanitary napkin, etc. Using these seaweed-based edible bioplastic could eliminate the usage of silicone paper in sanitary napkins.

Check out these 17 easy ways you can start reducing plastic waste in your every day life!

Did you know that of the 30 million tons of plastic waste generated in 2009 in the US alone, and only 7 percent of that was recovered for recycling? Here are 17 ways to reduce your plastic waste.